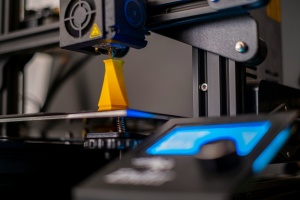

At its core, 3D printing—also known as additive manufacturing—builds objects layer by layer, offering unmatched flexibility in design and production. For the cycling industry, this means faster, more precise creation of accessories like bicycle phone mounts, bags, lights, and bottle holders. Unlike conventional manufacturing, which often requires costly moulds and lengthy setup times, 3D printing accelerates prototyping by weeks, reduces material waste, and enables small-batch production at a fraction of the cost. ODIER harnesses this technology to deliver products with pinpoint accuracy, ensuring that every design meets the rigorous demands of cyclists navigating bustling city streets or rugged trails. This blend of speed, customization, and cost efficiency is redefining what’s possible in cycling gear production.

For urban cyclists, 3D printing unlocks a new level of personalization, delivering gear tailored to their specific needs. Imagine a bicycle phone mount engineered with ergonomic grips and vibration-damping features, perfected through rapid 3D-printed prototypes to ensure a secure fit on any handlebar. Similarly, lightweight bottle holders designed for long rides are tested and refined with precision, enhancing the riding experience. For distributors, the appeal lies in the ability to bring exclusive, market-ready products to shelves faster than ever. A standout example is ODIER’s 2015 AS0 Summoner Intelligent Handlebar, which used 3D printing to streamline its development and went on to clinch an innovation award at the Shanghai International Bicycle Exhibition. This capability empowers distributors to offer cutting-edge cycling accessories that capture market trends and meet consumer demands with unprecedented agility.

ODIER’s approach to 3D printing is a masterclass in transforming ideas into tangible, high-quality products. The process begins with collaborative concept development, where client visions for custom cycling accessories are meticulously crafted into digital designs. These concepts are then brought to life through 3D printing, creating functional prototypes that undergo rigorous testing for durability and performance. Feedback drives iterative refinements, ensuring every detail—from the grip of a phone mount to the weight of a bottle cage—is optimized. Once perfected, designs transition to mould manufacturing for scalable production, enabling ODIER to deliver both small-batch niche products and high-volume orders with consistent quality. This seamless workflow underscores ODIER’s commitment to precision engineering and user-centric innovation.

As 3D printing technology evolves, it promises to push cycling gear into bold new territory. Emerging trends, such as the use of lightweight, eco-friendly materials and sustainable production methods, are set to redefine industry standards. ODIER is already investing in these next-generation technologies, positioning itself as a pioneer in creating cycling accessories that are not only high-performing but also environmentally conscious. By reducing waste and enabling rapid design iterations, 3D printing aligns with the growing demand for sustainable manufacturing practices. For retailers and distributors, partnering with a forward-thinking manufacturer like ODIER means access to innovative products that resonate with eco-conscious consumers and tech-savvy cyclists alike, ensuring a competitive edge in a rapidly evolving market.

About the Author

Dr. Rosemary Oswald is a materials engineer and cycling enthusiast with over 15 years of experience researching additive manufacturing and its applications in sports equipment design.

References

Additive Manufacturing Journal (2024): "Impact of 3D Printing on Prototyping Efficiency in Consumer Goods."

International Journal of Sports Technology (2023): "Innovations in Cycling Gear Design and Production."

Shanghai International Bicycle Exhibition (2015): "Innovation Award Case Studies."